Tactile Switches Explained: Selection, Design Tips, and How They Work

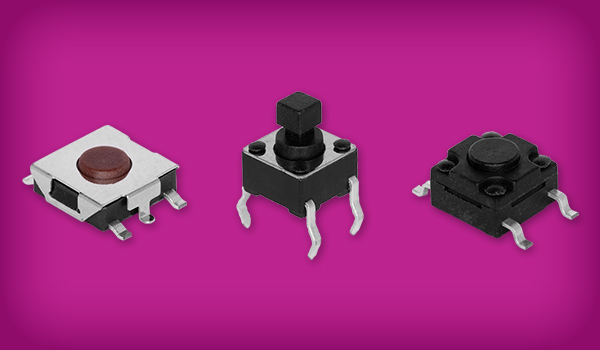

What are Tactile Switches?

A “tactile switch” is a widely used switch that completes an electrical circuit when pressure is applied to the device by the user, which then gives the user a perceptible “click” or haptic bump in response, indicating current flow. Current flow is turned off when the switch is released. To give a shorter definition, a tactile switch is a momentary action device whose operation is perceptible by touch. This tangible feedback gives some assurance to the user that the switch has operated and a signal has flowed. Tactile switch models are also available that turn off current when the switch is pushed and turn it back on when released. These “normally closed” tactile switches are also available from Same Sky.

Switches of this type began as membrane, or screen-printed switches in the early 1980’s for use in keyboards and keypads. Their lack of tactile feedback and poor performance was quickly met with resistance until the introduction of devices with metal domes as part of the switch design in the late 1980’s. The domed design provided tactile feedback along with a more robust method of actuation plus better longevity. Today, tactile switches are widely used as input devices across thousands of commercial and consumer devices.

Interested in more switches content? Check out our other blog topics:

- Fundamentals of Switches: A Guide to Types, Uses, and Selection

- Slide Switches Selection Guide: From Form Factor to Function

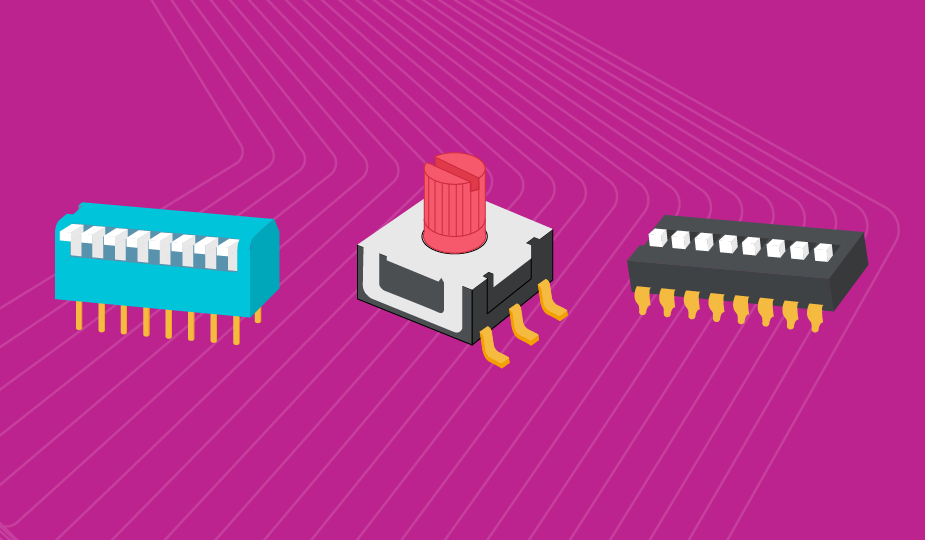

- What Are DIP Switches? A Guide to Types, Functions, and Uses

- Why Rotary DIP Switches Matter: Reliable Configuration for Modern Electronics

- Or watch our DIP Switches 101 video

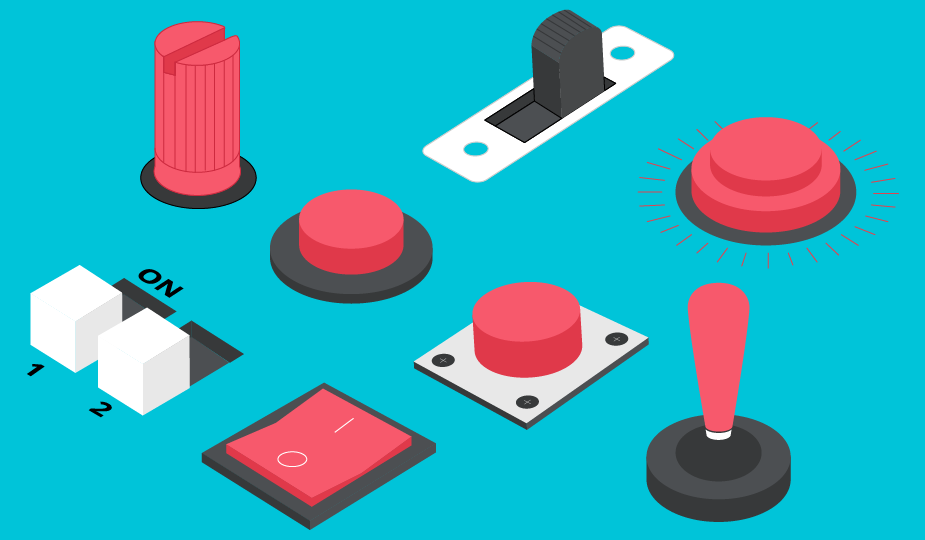

What’s the Difference Between a Tactile Switch and Push Button Switch?

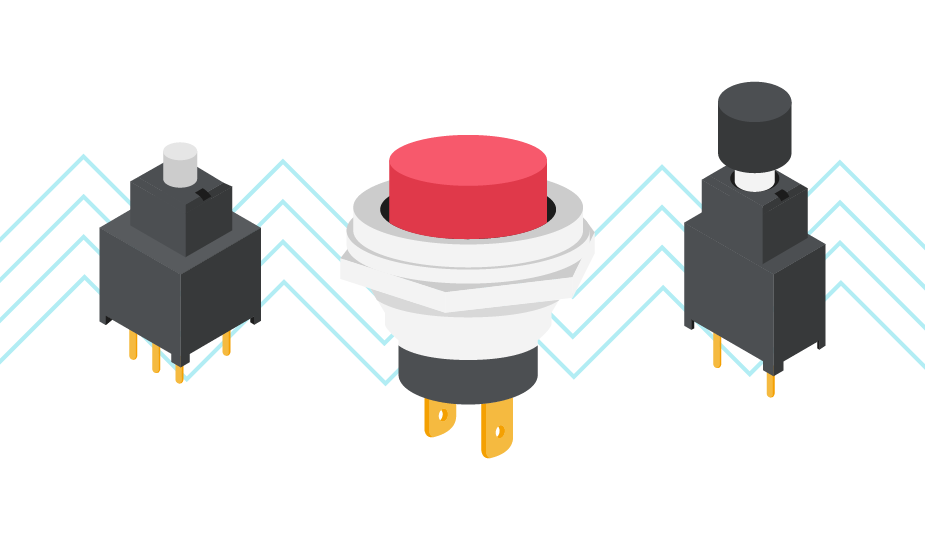

There can be some user confusion in the naming of tactile switches in that they are often referred to as push button switches. A push button switch is designed to allow current flow in a circuit when the actuator is depressed and goes a specified travel distance and stop the flow of current when pushed again. Push button switches can be mounted either on panels or directly on printed circuit boards (PCBs). To learn more about push button switches, read our Push Button Switches blog.

On the other hand, a tactile switch allows current flow when the actuator is pushed and held, and stops the current flow when it is released, or vice versa. There is minimal travel of the actuator. These are known as “momentary action” switches, and while some push buttons are momentary, all tactile switches are. Tactile switches are also typically much smaller than push button switches, and because of their design often carry lower voltage and current ratings. They also offer audio or haptic feedback and are exclusively designed to be directly mounted onto PCBs.

What Are the Benefits of Tactile Switches?

Tactile switches offer important and useful features that can enhance the user perception of a product. First, they provide momentary circuit engagement – the current is on when the switch is pushed and is off when the switch is released, or vice versa. This allows for faster data input, as in a computer keyboard, and continuous operation until necessary, as in a motor control keypad.

Second, and most important, tactile switches offer tactile and auditory feedback to the operator, confirming that the switch is engaged and power is flowing to the circuit. They also, as in the case of computer keyboards, provide a fulfilling physical “feel” to the function of typing that can also indicate missed strokes, or lack of input.

Third, tactile switches typically operate at lower power and current ratings. This makes them less costly to produce and better matched to low voltage devices and systems. The lower voltage also means less arcing at contact points.

Finally, with very few moving parts, tactile switches typically last longer than other mechanical switches. This allows for their use directly mounted on circuit boards, with less worry about removal for repair. It also means that, in comparison to other switch types, they cost less to use in a product.

How Do Tactile Switches Work?

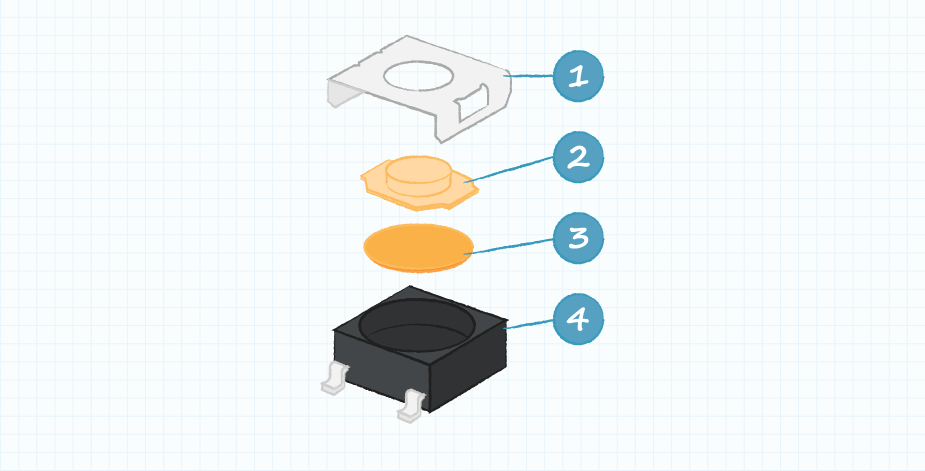

Tactile switches are somewhat elegant in their simplicity, employing a very limited number of parts to meet their intended function. The basic tactile switch design typically incorporates four parts, including the largest component - a molded resin base (4) containing terminals and contacts to connect the switch to the PCB base.

A contact dome (3) with an arched shape fits into the base and deflects, or reverses shape under force. This process produces the audible and haptic click of a tactile switch. The dome connects two fixed contacts in the base when flexed and thus powers the circuit. When the operating force is removed, the dome returns to its original shape and the circuit is interrupted. Domes are made of both metal and other materials depending on the amount of haptic and audible feedback required.

The plunger (2) sits on top of the contact dome and is pushed to flex the dome and activate the switch. Plungers can be made of metal, rubber, or other materials and can be flat or offer raised projections, depending on the needs of the overall product. The type of material used in the plunger and the contact dome will also determine the click tactile feel and sound.

On top of the plunger sits the cover (1), which protects the internal mechanism of the switch. This can be made of metal or other materials, depending on the intended use of the switch and the amount of protection needed. Specific covers can also include a ground terminal to protect against static discharge.

Tactile Switch Specifications

There are many design specifications applicable to tactile switches, including:

- Voltage Rating: (sometimes called rated power) indicates the maximum voltage that the switch can withstand when open or when closed. Voltage ratings on tactile switches are typically low.

- Current Rating: the maximum current in amps that a switch can carry before damage.

- Activation Force: (also called operating force) the amount of force or pressure (expressed in gram force or gf) that is needed to move an actuator on a switch.

- Deflection: (also called actuator travel) the overall travel distance of a depressed switch.

- Contact Force: the amount of force or pressure (expressed in grams) required for the switch to connect the terminals and cause power to flow.

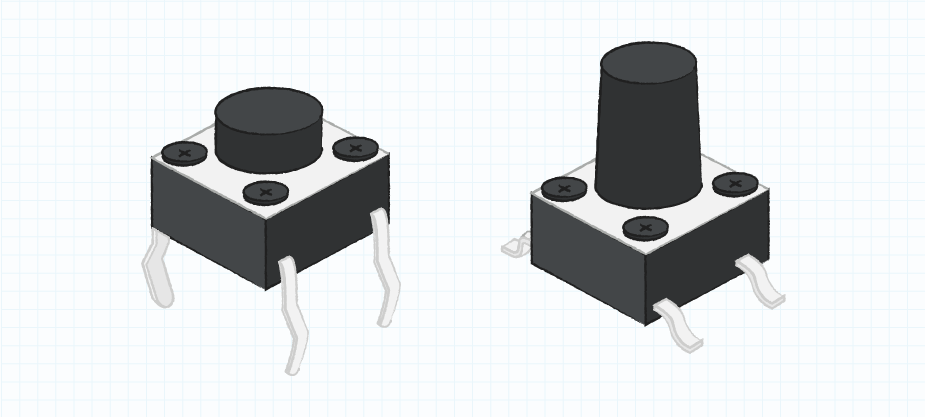

- Actuator Height: the height of the actuator above the body of the switch.

- Lifecycle Range: the expected duration of a switch under normal operating conditions.

- Temperature Range: the range of temperatures within which the switch will operate to specifications.

- Mounting Style: the method used to mount the switch on the PCB, either through hole or surface mount.

- IP Rating: an international standard that classifies the degrees of protection of a switch (or other product) against the intrusion of dust and liquids.

Selecting the right tactile switch for your product is not just a process of evaluating specifications on a product datasheet. Tactile switches, due to their “feel” and “sound” can influence the user perception of quality in the overall product. This perception can be difficult to quantify. The force needed to activate the switch and the haptic feedback the user senses must meet the application and will vary from consumer to industrial products.

It is often wise to match the characteristics of a particular switch to its application by testing the actual switch in prototype use. For example, an automotive switch may require more actuation force to avoid input errors caused by vehicle vibration. A switch used on a printer or a consumer gaming product can be less sensitive. Of course, in either case the switch must also function reliably over the lifetime of the product.

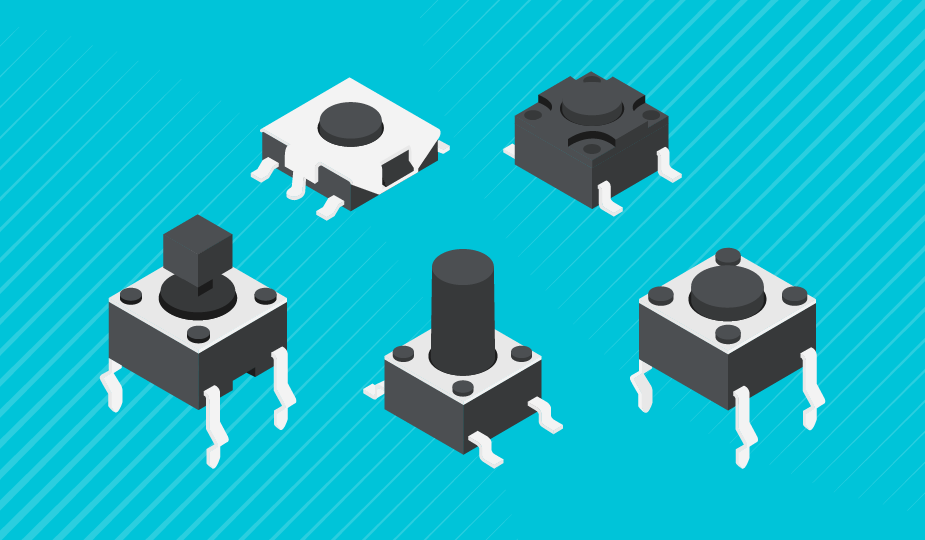

Types of Tactile Switches

Tactile switches are available in two major types, either standard (or open), or sealed. The standard type of tactile switch is not sealed to outside elements like dust, gases, or water. The sealed type has mechanical elements to protect the internal parts from dust and water ingress in harsh environments.

Some of the different types of tactile switches that are available include:

- Round/Square/Rectangular

- Flush

- Illuminated

- Miniature

- Micro

- Right Angle

- Long Stroke

- 5-Way

- Switch Arrays & Keypads

How to Wire a Tactile Switch

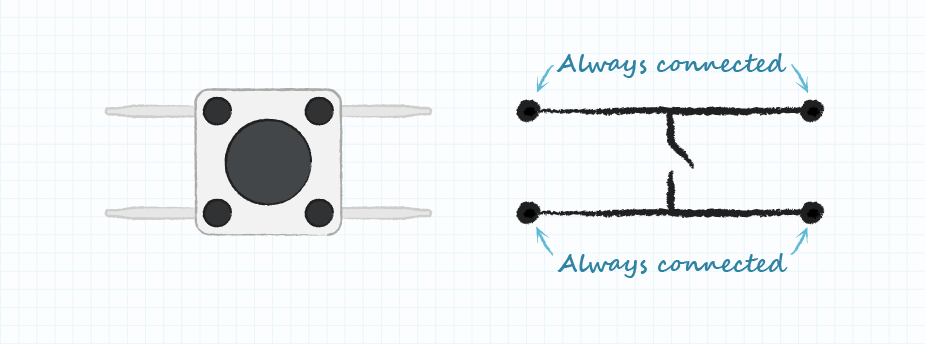

Tactile switches typically contain 4 pins. These pins are internally connected into 2 sets. The purpose of using 4 pins is to provide stability when the device is mounted on a circuit board. When wiring, you technically only need to use 2 of the leads, but it is best practice to use all of the pins possible, while realizing that the pairs are connected internally. Tactile switches are also available with just 2 pins. There are also 5-pin tactile switches available to allow for joystick-like control in a very small package.

What Are Common Tactile Switch Applications?

Due to their small size, low height, and long life, tactile switches fit many needs in various types of consumer and industrial products. A list of some of the typical applications include:

- Keyboards & Keypads

- Remote Controls

- Game Controllers

- Phones

- Toys

- Musical Instruments

- Notebook Computers

- Appliances

- Security Electronics

- Industrial Controls

- Electrical & Electronic Instruments

- Portable Equipment

- Medical Equipment

Some newer applications that take advantage of the small footprint, light weight, and durability of tactile switches include wearable technology, smart body armor, and body cameras.

Conclusion

Tactile switches are an intelligent choice when low-power, momentary action power control or data input is required in a product, and where tactile and auditory feedback is a desirable feature. Same Sky offers a line of tactile switches featuring compact packages, a range of actuator heights, and multiple configuration options.

Key Takeaways

- Tactile switches are compact, momentary switches that provide audible and physical feedback when actuated.

- Tactile switches are widely used in consumer electronics, automotive controls, medical devices, and industrial equipment.

- Known for their low profile and precise actuation, tactile switches are ideal for space-constrained PCB designs.

- Tactile feedback helps confirm user input, enhancing interface reliability and usability in human-machine interactions.

- Common tactile switch configurations include standard, sealed, surface mount (SMT), and through hole types.

- Key tactile switch selection factors include actuation force, actuator height, travel distance, terminal type, operating life, and IP rating.

- Engineers value tactile switches for their cost-effectiveness, ease of integration, and long mechanical lifespan in low-current applications.