Rotary Encoder Improvements Save Power in Mobile Robotics

Commercial mobile robotics are spawning vast markets for equipment and services. Opportunities for aerial drones alone are expected to soar to more than $50 billion by 2030 according to recent research. On the ground, mobile robots are being utilized in a tremendous variety of scenarios – industrial, commercial, and domestic – to perform tasks faster and more cost-effectively than humans, to operate in environments unsuitable for humans, or in collaborative roles to relieve workers of repetitive or physically demanding tasks.

Mobility drives the need for battery-powered operation, and as a result, energy efficiency throughout the entire vehicle becomes of critical concern to maximize the operating range. Careful management of a limited power budget is essential to enable the robot to work longer or travel further on a full charge. This is true whether it is a drone needing to travel as far as possible to deliver food aid, a warehouse assistant that must deliver maximum uptime to boost the operator’s bottom line, or a domestic robot such as a vacuum cleaner or lawnmower whose market appeal is directly related to the amount of work it can do between charges. Greater efficiency also gives designers extra freedom to manage cost, size, and weight by enabling robots to go further on smaller batteries.

The choice of encoder, used to capture the position information the controller needs to execute the motor’s vector-control algorithm, can have an important influence on the system’s energy efficiency. In multi-motor systems, the energy savings achievable by selecting an efficient encoder can have an appreciable effect on the power budget. Among the encoder technologies available today, capacitive encoders can not only boost efficiency, but also enable greater reliability, reduce maintenance, lower development costs, and accelerate time to market. This article will dive into the most common encoder technologies and their role in the growing markets for autonomous mobile robots in greater detail.

Applications for Autonomous Mobile Robots Are Expanding

Until recently, autonomous robots and aerial drones have been more or less the sole preserve of large corporations and government agencies such as the military. Now, however, the technologies are becoming more affordable, and a wide variety of low-cost commercial applications are hitting the market. The largest growing markets for autonomous mobile robots (AMRs) are, but not limited to, the following:

- Logistics and warehouse AMRs transport goods using mapping and scheduling algorithms

- Industrial mobile robots assist in material handling and production processes in smart factories

- Autonomous forklifts and carts are being used in automated warehouses for pallet movement

- Inspection and surveillance robots deployed in facility monitoring, security, and hazardous environment inspections

- Medical and service robots used in hospitals for medication delivery or disinfection tasks

- Autonomous agricultural robots perform planting, weeding, and harvesting using AI-driven decision-making

- Self-driving vehicles and drones, which include delivery robots, autonomous cars, and UAVs for various commercial applications

Making Small Savings, Comparing Encoder Options

Meaningful improvements in flying range or operating time require a multitude of small power savings across all on-board subsystems. Because mobile robots often have several electric motors to move actuators or positioning mechanisms, such as camera gimbals, a small increase in motor-controller efficiency can deliver a much larger overall gain. Controlling and commutating the motor is critically dependent upon knowing the rotor’s angular displacement at any time. Optical and magnetic encoders are two popular choices to achieve this task, but each have their drawbacks.

Optical & Magnetic Encoders

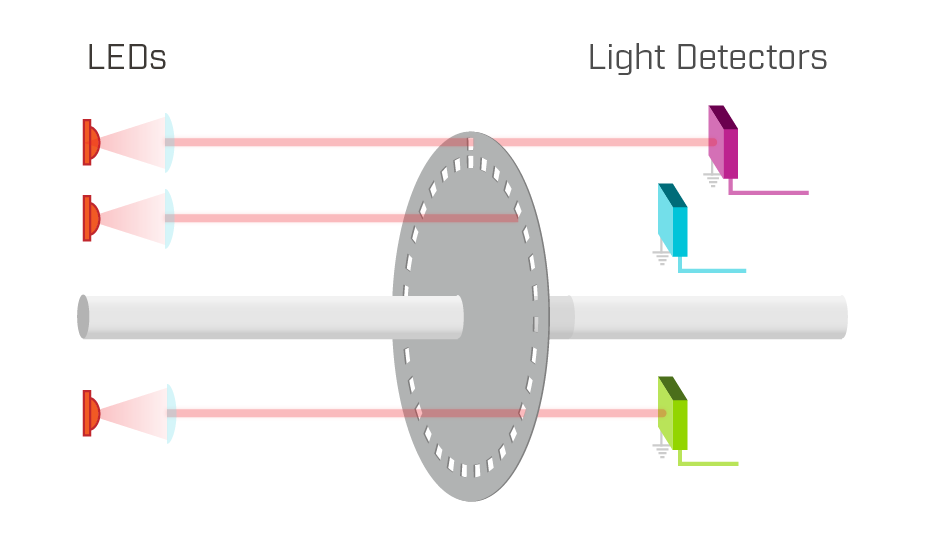

An optical encoder comprises an LED-source and optical-sensor combination that detects light transmitted through or reflected from a code wheel mounted on the motor shaft. Two LEDs positioned in quadrature enable detection of both motor speed and direction. A third LED may be used to monitor a single marking on the code wheel, to provide an indexing pulse to the motor-control system.

The encoder resolution, in terms of pulses per revolution (PPR), is dependent on the number of precision-spaced markings on the code wheel. Optical encoders can have very high resolution but also suffer from several weaknesses. These include vulnerability to dust, grease, or condensation, which can collect on the code wheel and cause missed or false readings. In addition, LED brightness will lessen over time and ultimately burn out, leading to failure that can only be remedied by replacing the encoder.

As far as energy efficiency is concerned, it is true that optical encoders draw relatively high current, which increases at higher resolution settings and with more complex output-signal formats. In fact, the current consumption can more than double from the lowest to highest resolution. Some encoders can draw as much as 85 mA at the highest resolution. This may not sound important next to the power consumed by the motor, but at 5 V and 85 mA the encoder consumes 0.425 watts. In a four-motor system the encoders alone are responsible for 1.7 watts. Reducing this drain on the battery’s energy could allow the application to run other systems such as an on-board camera, sensors, or small actuators for a considerable length of time.

Magnetic encoders provide an alternative that does not require line of sight and therefore are not vulnerable to errors due to contamination. In addition, magnetic encoders are able to operate even when immersed in non-conductive fluids such as gear oil. On the other hand, the positional resolution and accuracy is typically lower in comparison to optical encoders. Depending on the type of magnetic encoder, the maximum current can range anywhere from 20 mA to 160 mA or more.

Capacitive-Based Rotary Encoders Save Power and More

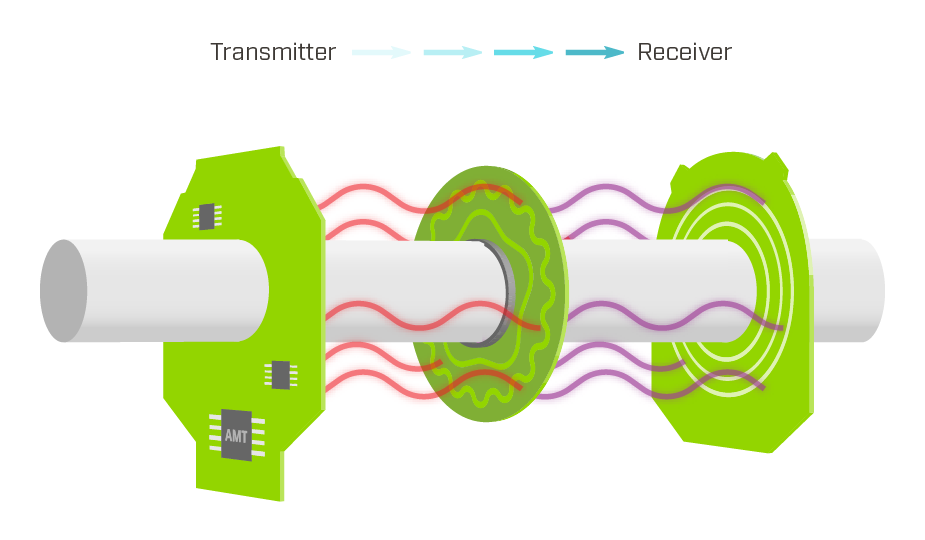

Same Sky’s AMT rotary encoders based on capacitive technology are a power-efficient alternative. Employing the same operating principle as a digital Vernier caliper, the sensor comprises a fixed body and one moving element that together forms a variable capacitor. As the encoder rotates, this capacitor produces a unique but predictable signal that can be used to calculate the position of the shaft and direction of rotation. With the help of an onboard processor, the ASIC and a microprocessor can work together to generate more complex outputs, such as the commutation pulses necessary for brushless dc (BLDC) motors or serial outputs in absolute encoders.

The capacitive operating principle allows the encoder to maintain accuracy in dusty or dirty environments, such as in a warehouse, on a factory floor, or in equipment deployed outdoors. Like magnetic technology, capacitive encoders can also be submerged in non-conducting fluids such as gear oils. This can save expensive sealing of the code wheel enclosure and minimize demand for routine cleaning or replacement of the disk, which is often needed when using optical encoders. At the same time, the capacitive encoder provides equivalent or superior accuracy compared to other encoder technologies, with a typical accuracy value of 0.2 degrees.

When it comes to energy efficiency, AMT capacitive encoders also boast huge advantages. For example, the AMT10 and AMT10E encoders draw less than one-tenth of the current of a comparable optical encoder, which can yield significant power savings in a system. The table below compares the AMT10 and AMT10E and their 5 V and 6 mA power consumption with examples of competing optical and magnetic encoders in a four-motor system.

| Encoder model | Type | Operating voltage | Current at highest resolution | Power in 4-motor system |

|---|---|---|---|---|

| AMT10/10E | Capacitive | 5 V | 6 mA | 0.12 W |

| Competitor 1 | Optical | 5 V | 85 mA | 1.7 W |

| Competitor 2 | Magnetic | 5 V | 160 mA | 3.2 W |

Outside of the AMT10 and AMT10E series, Same Sky’s additional AMT incremental, absolute, and commutation capacitive encoder series only draw power at 5 V and 16 mA, which still represents major power savings compared to optical and magnetic encoders.

As well as saving enough power to meet the entire needs of other on-board subsystems, capacitive based rotary encoders require less servicing than optical encoders, which can require cleaning to restore accuracy. Magnetic encoders – although robust – often have less accuracy than optical or capacitive types and can consume almost twice the power of an optical encoder.

If a robot has multiple motors for various tasks, replacing all of the optical or magnetic rotor-position encoders with capacitive encoders can trim enough from the overall power budget to run a subsystem like a GPS module, wireless communication, or sensing, so that more of the battery’s energy can be used to extend the vehicle’s working range.

One final point worth mentioning is the growing popularity of capacitive-based absolute encoders in robotics, such as Same Sky’s AMT21, AMT22, and AMT24 series. While both incremental and absolute encoders can be used for measuring the speed, direction, and position of a rotating shaft, absolute encoders have the added capability to output shaft position at any time, including power on. This eliminates the need for a homing sequence necessary for an incremental encoder. Absolute encoders are also able to provide the true position in real time with minimal latency, making them ideal for autonomous mobile robotics applications in need of precise position data. Our blog, When is an Absolute Encoder Right for Your Design, outlines this topic in greater detail.

What Does the Future Hold?

With the proliferation of mobile robotics comes the need for battery-powered operation, and as markets develop and end users become more demanding, every milliampere-hour of battery energy will become increasingly precious. Careful management of a limited power budget is essential to enable the robot to do more work and operate for longer on each full charge. Moreover, as greater efficiency minimizes energy waste, engineers can exploit the opportunity to specify smaller and lighter batteries, thus realizing further improvements in operation and reducing application size.

The mobile and aerial platforms now emerging incorporate large numbers of electric motors, not only for driving wheels or rotors, but also in various positioning mechanisms and actuators that often require motion control in multiple axes. Motor power consumption may range from several watts in a small positioning mechanism to tens of watts or sometimes considerably more for traction or lift. Each motor has an associated driver/controller unit that also dissipates significant power. Minimizing the power consumed by each motor system liberates more battery energy for useful work, and the cumulative effect across multiple motors can deliver a valuable advantage in the quest to build robots that can go further on smaller batteries.

Affordable automation in the form of small mobile robots and civil drones will continue to revolutionize activities such as manufacturing, distribution, and asset management. Rotary encoders utilizing capacitive technology could play a small part in this exciting mobile robotics revolution, unlocking power savings much greater than some might imagine. More generally, they can also help producers of many different applications meet efficiency regulations, such as the EU’s IEC 60034-30-1 standard, which defines efficiency levels for three-phase induction motors. But thanks to these small, energy-efficient devices, motor-driven equipment everywhere could be running longer and using less energy than ever.